I. Ukubaluleka Kokukhetha Amaketango Namaketango Alungile

Ezimbonini zikasimende, izinyusi zamabhakede zibalulekile ekuthutheni izinto eziyinqwaba ezisindayo ezifana ne-clinker, i-limestone, nosimende zibheke phezulu.Isixhumanisi esiyindilinga amaketango namaketangozithwala ukucindezeleka okukhulu kwemishini, okwenza umklamo wabo nokulawulwa kwekhwalithi yokukhiqiza kubaluleke kakhulu ukuze kuphumelele ukusebenza. Nakhu ukuthi kungani kubalulekile ukukhetha izingxenye ezifanele nokuthi i-SCIC ibhekana kanjani nalokhu:

1. Ikhono Lokuthwala:Amaketanga namaketangakumele imelane nemithwalo eqinile ephezulu kanye nemithelela yokushaqeka evela kumnyakazo wamabhakede oqhubekayo. Izingxenye ezisezingeni eliphansi zisengozini yokwehluleka okungazelelwe, okuholela ekuphelelweni kwesikhathi, ezingozini zokuphepha, nasekulungiseni okubizayo. Ukunamathela kwe-SCIC ezindinganisweni ze-DIN kuqinisekisa ukuthi imikhiqizo yethu ihlangabezana nezidingo zamandla ezidingekayo, njengamandla athile okunqamuka okungu-280–300 N/mm².

2. I-Wear Resistance: Imvelo yokugwazeka yezinto zikasimende isheshisa ukuguga ezingxenyeni zekheshi. Amaketango aqiniswe yikesi (afika ku-800 HV) namaketango (afika ku-600 HV) ahlinzeka ngendawo eqinile ukuze amelane nokuhuzuka, kuyilapho egcina ukuqina okuyinhloko ukuvimbela ukuqhekeka. Inqubo enembile ye-SCIC yokungcwatshwa kwe-carburizing ifinyelela ugqinsi oluceliwe luka-10% kanye nokujula kokuqina okusebenzayo okungu-5–6%, okuqinisekisa ukusebenza kwesikhathi eside.

3. Ukuthobela Amazinga: Ukuhambisana ne-DIN 764, DIN 766, DIN 745, kanye ne-DIN 5699 kuqinisekisa ukuthiamaketanga namaketangahlangabezana nezilinganiso zomkhakha zobukhulu, izakhiwo zezinto ezibonakalayo, nokuthembeka. Ubungcweti be-SCIC bokuhlangabezana nalawa mazinga buqinisekisa ikhwalithi engaguquki eyenzelwe izinhlelo zokusebenza ezinzima.

4. Ukulawulwa Kwekhwalithi Yokukhiqiza: Ukulawulwa kwekhwalithi okuqinile kwe-SCIC—kusuka ekukhetheni impahla kuya ekuhlolweni kokugcina—kunciphisa amaphutha futhi kuqinisekise ukunemba kobukhulu, ubulukhuni, namandla. Leli khono linciphisa amathuba okwehluleka ngaphansi kwezimo ezinzima zezimboni zikasimende.

Ukukhetha okulungileamaketanga namaketangakubalulekile ekusebenzeni kahle nasekuphepheni kwezikheshi zakho zamabhakede. Kwa-SCIC, imikhiqizo yethu iklanywe futhi yakhiwe ukuze ihlangabezane nezindinganiso eziqinile ze-DIN, iqinisekisa ukuthi ingakwazi ukumelana nemithwalo esindayo nezinto ezihugayo ezivamile ezimbonini zikasimende. Ngokulawula kwethu ikhwalithi okuqinile, ungathemba ukuthi amaketanga namaketanga azohlinzeka ngokusebenza okuthembekile, kunciphise ubungozi bokwehluleka okungalindelekile kanye nezindleko zokunakekela.

II. Ukulinganisa Ukuqina namandla Ngesikhathi Sokukhiqiza

Ukuzuza ubulukhuni bobuso obushiwo iklayenti (800 HV yamaketango, 600 HV yamaketango), ukujiya kwe-carburizing (10% we-diameter yesixhumanisi), ukujula kokuqina okusebenzayo (550 HV ku-5–6% wedayamitha), kanye namandla okuphuka (280–300 N/mm²) kudinga ukulingana okucophelela phakathi kokuqina namandla. Nansi indlela i-SCIC ekufeza ngayo lokhu ngokukhethwa kwezinto, ukwelashwa kokushisa, nokungcwatshwa kwe-carburizing:

Izinqubo Zokukhiqiza Ezibalulekile

1. Ukukhethwa Kwezinto:Izinsimbi ezinekhabhoni ephezulu noma i-alloy zikhethwa ngenxa yekhono lazo lokuphendula ukungcwatshwa kwe-carburizing kanye nokucisha, okuhlinzeka kokubili ubulukhuni bobuso kanye nokuqina okuyisisekelo.

2. Carburizing:I-Carburizing isakaza ikhabhoni endaweni yensimbi ukwandisa ubulukhuni. Ngesixhumanisi seketango elinobubanzi obungama-20 mm;Ukujula kweCarburizing: 10% ka-20 mm = 2 mm;Ukujula Kokuqina Okuphumelelayo: 5-6% ka-20 mm = 1-1.2 mm ku-550 HV;Lokhu kudala indawo eqinile, engagugi kuyilapho kugcinwa i-ductile core ukuze imunce imithwalo eguquguqukayo.

3. Ukwelashwa Kokushisa:Ukucisha: Ngemva kokungcwatshwa kwe-carburizing, izakhi ziyacishwa ukuze kukhiywe ubulukhuni bobuso (800 HV ngamaketanga, 600 HV ngamaketango);Ukushisa: Ukushisa okulawulwayo (isb, ku-200–250°C) kulungisa izici zomongo, ukuqinisekisa ukuqina namandla okuphuka adingekayo angu-280–300 N/mm². Ukuthukuthela ngokweqile kunciphisa ubulukhuni, kuyilapho ukwehlisa ulaka kuyingozi.

4. Umthetho Wokulinganisa: Ukuqina: Ubulukhuni obuphezulu bumelana nokugqoka okuvela ezintweni eziqhumayo;Amandla: Ukuqina okuyinhloko kuvimbela ukuphuka okuphukayo ngaphansi kwemithwalo eqinile.I-SCIC ilawula ukujula kwe-carburizing kanye namapharamitha okushisa ukuze igweme ukuba brittleness ngokweqile ngenkathi ihlangabezana nezicaciso zeklayenti.

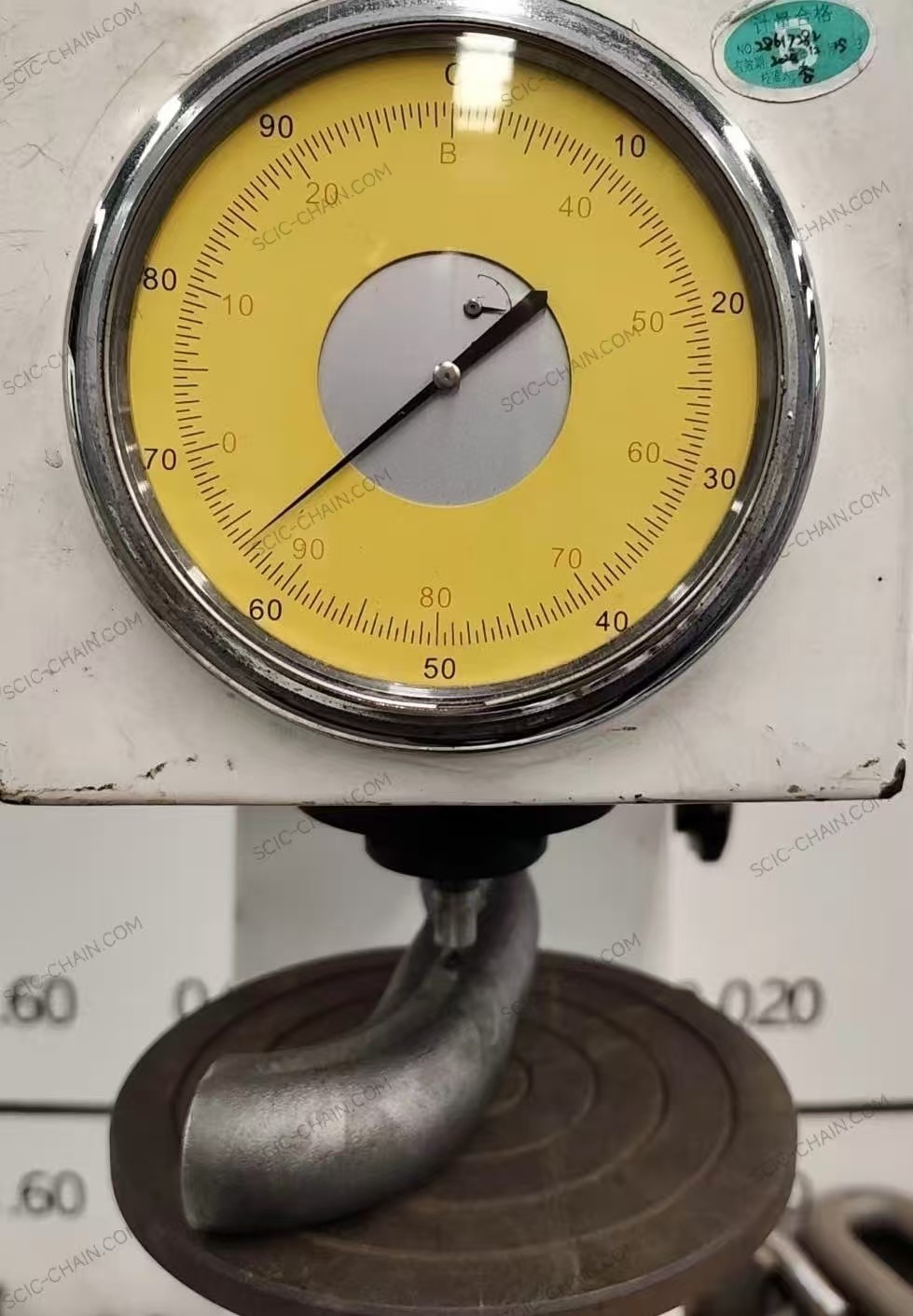

(izixhumanisi zamaketanga ezinokuqina okuphezulu kwe-carburized surface)

(izixhumanisi zamaketanga ezinobunzima obuphezulu be-carburized surface, ngemuva kokuhlolwa kwamandla okuphula)

Inqubo yethu yokukhiqiza ilawulwa ngokucophelela ukuze sifinyelele ukulingana okuphelele phakathi kokuqina namandla. Ngokusebenzisa i-carburizing enembile kanye nokwelashwa kokushisa, siqinisekisa ukuthi wethuamaketanga namaketangaube nendawo eqinile, engagugi ngenkathi ugcina ingqikithi eqinile yokusingatha imithwalo eguquguqukayo emisebenzini yakho. Le bhalansi ibalulekile ekwandiseni ubude bempilo kanye nokuthembeka kwemishini.

III. Ukuqinisekisa Isikhathi Sokuphila Ngokusebenza Nokunakekela

Ngisho ngeamaketango namaketanga asezingeni eliphezulu, ukusebenza nokugcinwa ngendlela efanele kubalulekile ukuze kwandiswe isikhathi sokuphila ezikheshisini zamabhakede zasefekthri kasimende. I-SCIC inikeza isiqondiso esilandelayo kumakhasimende:

Imihlahlandlela Yokunakekela

1. Ukuhlola Okuvamile:Hlolaamaketanga namaketangangezimpawu zokuguga, ezifana nobude (isb, >2–3% wobude bangempela), ukuwohloka, noma ukuqhekeka kwendawo. Ukutholwa kusenesikhathi kuvimbela ukwehluleka.

2. Ukuthambisa:Faka amafutha okushisa aphezulu, umsebenzi osindayo ukuze unciphise ukungqubuzana nokuguga. Gcoba njalo ngamahora okusebenza ayi-100–200, kuye ngezimo.

3. Ukuqapha Ukuqina:Gcina ukuqina kweketango elilungile ukuze ugweme ukuxega ngokweqile (okubangela ukugedla) noma ukuqinisa ngokweqile (ukuguga okwandayo). Lungisa ngokwezicaciso ze-SCIC.

4. Ukushintshwa Kwesikhathi:Shintshanisa izingxenye ezigugile noma ezilimele ngokushesha ukuze uvimbele ukuhluleka kwe-cascading. Isibonelo, i-shackle ekhubazekile kufanele ishintshwe ngokushesha.

5. Izindlela Ezinhle Zokusebenza:Sebenza ngaphakathi kwemikhawulo yedizayini (isb, gwema ukulayisha ngokweqile okungaphezu kwamandla okunqamula amandla angu-280–300 N/mm²) ukuze unciphise ingcindezi.

Ukuze ukwandise isikhathi sokuphila samaketango namaketango, landela lezi zindlela: hlola njalo ukuguga, uqinisekise ukugcotshwa okufanele, qapha ukushuba kweketango, bese ubuyisela izingxenye ezilimele ngokushesha. Ngokunamathela kule mihlahlandlela nokusebenza ngaphakathi kwemikhawulo yedizayini, unganweba kakhulu ukwethembeka nokusebenza kahle kwamakheshi akho ebhakede.

I-Case Study: I-Real-World Impact

Isimo:

Imboni kasimende ibhekane nokuhluleka kwezintambo eziyindilinga eziyindilinga, isikhathi sokuphumula esingamahora ayi-10 ngenyanga ngenxa yamaketanga anobunzima obungama-HV angama-600 kanye nokushona kwe-carburizing okungajulile. Lokhu kwaholela ezindlekweni eziphezulu zokulungisa nokulahlekelwa ukukhiqizwa.

Isixazululo:

Ifekthri yamukela amaketanga esixhumanisi ayindilinga aqinile e-SCIC:

- Amapharamitha: 30mm ububanzi, 800 HV ubulukhuni bobuso, 3mm carburizing ukujula, 1.8mm ubulukhuni obusebenzayo ku-550 HV, 290 N/mm² amandla okuphuka.

- Isondlo: Ukuhlolwa kabili ngesonto, ukugcotshwa njalo ngamahora angu-150, nokulungiswa kokungezwani komzimba.

(izixhumanisi zamaketanga ezinokujula kwe-carburizing okuthuthukisiwe ukuya kububanzi besixhumanisi obungu-10%)

IV. Imiphumela

1. Isikhathi sokuphumula: Sehliswe ngo-80% (kuya emahoreni angu-2/ngenyanga).

2. Ubude besikhathi sokuphila: Amaketanga athatha izinyanga eziyi-18 (vs. 6 izinyanga ngaphambili).

3. Ukonga Izindleko: Izindleko zokunakekela zehle ngo-50% ngonyaka.

Lokhu kubonisa ukuthi izingxenye ze-SCIC zekhwalithi ephezulu neziqondiso zokunakekelwa ziletha kanjani izinzuzo ezibonakalayo.

V. Isiphetho

1. Ukukhetha Izingxenye Ezilungile:Amaketango namaketango athobela i-DIN e-SCIC, esekelwe ukuklama okuphezulu nokulawulwa kwekhwalithi, kuqinisekisa ukuphepha nokusebenza kahle kumakheshi wamabhakede efektri usimende.

2. Ukulinganisa Ukuqina Nokuqina: Izinqubo zethu zokukhiqiza ezinembile zihlangabezana nokucaciswa kwamakhasimende, ukuletha ukumelana nokuguga kanye namandla okuthwala.

3. Ukwandisa Ubude Besikhathi Sokuphila: Isiqondiso esisebenzayo sokunakekela siqinisekisa ukwethembeka kwesikhathi eside.

Ngokubambisana ne-SCIC, amaklayenti athola ukufinyelela kumaketango namaketango aklanywe ngobungcweti, afanelana nezidingo zawo, futhi asekelwa amasu afakazelwe okuthuthukisa ukusebenza nokunciphisa izindleko.

Isikhathi sokuthumela: Apr-21-2025