Amasistimu e-Conveyor ayingxenye ebalulekile yezimboni eziningi, ahlinzeka ngendlela yokuhamba kalula kwezinto nemikhiqizo.Amaketanga ensimbi ayindilingazivame ukusetshenziswa kumasistimu okuthutha avundlile, athambekele, naqondile, anikeza amandla adingekayo nokuqina ukuze amelane nobunzima bokusebenza okuqhubekayo. Kule bhulogi, sizohlola ukubaluleka kokumelana nokugqokwa kwamaketango kumasistimu okuthutha kanye nezici ezibalulekile ezinomthelela kukho.

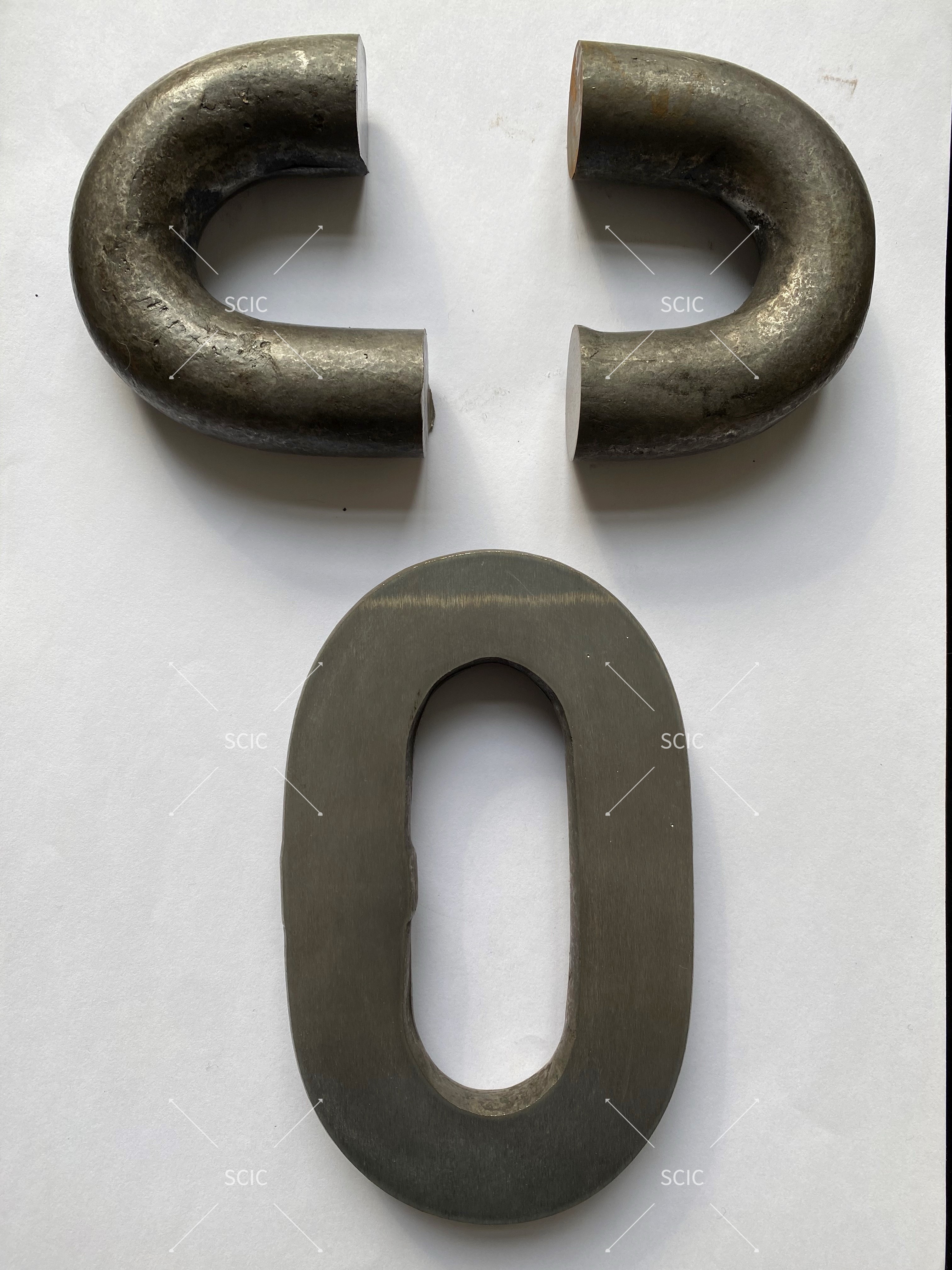

I-SCIC round link amaketanga ensimbiakhiwe ngensimbi ye-CrNi alloy, eyaziwa ngamandla ayo aqinile okuqinile kanye nezakhiwo zokulwa nokugqwala. Amaketango enza inqubo yokungcwatshwa kwe-carburizing ukuze kuthuthukiswe ubulukhuni bawo bobuso, ngobubanzi obuqondiwe obungu-57-63 HRC (isikali sokuqina kwe-Rockwell). Leli zinga eliphakeme lobulukhuni liqinisekisa ukuthi amaketanga angakwazi ukumelana namandla abrasive kanye nokugqoka okuhambisana nokudlulisa imithwalo esindayo esikhathini eside.

Ngaphezu kokuqina kobuso, ubulukhuni bendawo ewumgogodla wamaketango nawo bubalulekile ekunqumeni ukumelana kwawo nokugqokwa kwawo sekukonke. Amaketanga e-SCIC akhiwe ukuze abe nobulukhuni bendawo obuyingqikithi obungu-40-45 HRC, okushaya ibhalansi efanele phakathi kokuqina nobulukhuni. Le nhlanganisela yezakhiwo zobulukhuni ivumela amaketanga ukuthi amelane nokuguquguquka futhi agcine ubuqotho bawo besakhiwo ngaphansi kwemithwalo ehlukahlukene kanye nezimo zokusebenza.

Ukujula kwe-carburizing kwamaketanga kungenye into ebalulekile ethonya ukumelana kwabo nokugqoka. Amaketanga e-SCIC aklanyelwe ukuthi abe nokujula kwe-carburizing kufika ku-2.5mm, okuqinisekisa ukuthi ungqimba oluqinile ludlulela ekujuleni kwento. Lokhu kujula kunomthelela ekuqineni kukonke kwamaketanga, kuhlinzeke umgoqo ovikelayo ekugugeni nokwelula impilo yabo yesevisi.

Ukuqinisekisa ubulukhuni nokugqoka ukumelana kwamaketanga, ukuhlolwa okuqinile kwenziwa ukukala izakhiwo zabo. Umbiko wokuhlola ubulukhuni beketango uyakhiqizwa, uchaza imingcele ethile njengokuqina kwendawo, ubulukhuni bendawo eyinhloko, nokujula kwe-carburizing. Lokhu kuhlola okuphelele kunikeza isiqinisekiso sekhwalithi nokusebenza kwamaketango, okunikeza amakhasimende ukuzethemba ekuthembekeni kwawo kwezicelo ezifunayo.

Ngaphandle kwempahla nokwelashwa kokushisa, ukuklama nokwakhiwa kwamaketanga kudlala indima ebalulekile ekuphikisweni kwabo kokugqoka. Kusetshenziswa imicu yamaketango alinganiswe kakhulu, okuqinisekisa ukuthi isixhumanisi ngasinye sihlangabezana nezicaciso eziqinile zokunemba kobukhulu nokungaguquguquki. Lokhu kukhiqiza okunembayo kuphumela ezimpahleni zamaketango ezinembe kakhudlwana, ezizuzisa kakhulu izinhlelo zokusebenza ezinemicu eminingi lapho ukufana kubalulekile ukuze kusebenze kahle.

I-geometry esebenza kahle yamaketanga, ngokuhlangana nezingxenye ezihambisanayo namasondo, ithuthukisa ngokwengeziwe ukumelana kwabo nokugqoka. Isixhumanisi se-interlink siklanywe ngokucophelela ukuze kuncishiswe ukungqubuzana nokuguga, ukukhuthaza ukudluliswa kwamandla okuphumelelayo kanye nokunciphisa ingozi yokwehluleka ngaphambi kwesikhathi. Lokhu kunaka kwemininingwane ekuklanyweni kweketango kunomthelela ekuphileni kwayo isikhathi eside kanye nokwethembeka kumasistimu okuthutha.

I-SCIC round link amaketanga ensimbiamasistimu okuthutha atholakala ngosayizi abahlukahlukene, okuhlanganisa 16 x 64mm, 18 x 64mm, 22 x 86mm, 26 x 92mm, kanye no-30 x 108mm, ahlinzekela uhla olubanzi lwezidingo zesistimu yokuthutha. Kungakhathaliseki ukuthi isetshenziswa ezimayini, zikasimende, zensimbi, noma kwezinye izimboni ezisindayo, lawa maketango aletha ukumelana nokusebenza okukhethekile, aqinisekisa imisebenzi yokuphatha engaphazamiseki.

Ukumelana nokugqokwa kwamaketanga ensimbi ayindilinga kuyisici esibalulekile sokufaneleka kwawo kumasistimu okuthutha. Ngokuhlanganisa ubulukhuni obuphezulu bobuso, ubulukhuni bendawo ewumgogodla, nokujula kwe-carburizing, kanye nokuklama okucophelelayo nokuhlola, amaketanga e-SCIC anikeza ukuqina nokuthembeka okukhethekile ezinhlelweni ezifunwayo. Uma ebhangqwe nokugcinwa okufanele kanye nokugcotshwa, lawa maketango angaba nomthelela ekusebenzeni okungenamthungo nokusebenza kahle kwamasistimu okuthutha, azuzise ekugcineni ukukhiqiza kanye nenzuzo yokusebenza kwezimboni.

Isikhathi sokuthumela: Feb-28-2024